8 Simple Techniques For Alcast Company

Table of ContentsAlcast Company Fundamentals ExplainedThe Greatest Guide To Alcast Company3 Simple Techniques For Alcast CompanySome Of Alcast CompanyGetting The Alcast Company To WorkIndicators on Alcast Company You Should Know

The subtle difference hinges on the chemical material. Chemical Comparison of Cast Light weight aluminum Alloys Silicon advertises castability by reducing the alloy's melting temperature level and boosting fluidness throughout spreading. It plays an essential function in enabling complex molds to be filled accurately. In addition, silicon adds to the alloy's stamina and wear resistance, making it important in applications where resilience is crucial, such as automotive components and engine components.It additionally enhances the machinability of the alloy, making it less complicated to process right into completed products. In this way, iron contributes to the overall workability of light weight aluminum alloys.

Manganese adds to the toughness of light weight aluminum alloys and improves workability (aluminum foundry). It is generally made use of in functioned light weight aluminum products like sheets, extrusions, and profiles. The existence of manganese aids in the alloy's formability and resistance to fracturing during fabrication procedures. Magnesium is a lightweight element that offers toughness and impact resistance to light weight aluminum alloys.

Top Guidelines Of Alcast Company

Zinc enhances the castability of aluminum alloys and helps regulate the solidification process during casting. It improves the alloy's toughness and hardness.

The primary thermal conductivity, tensile strength, return toughness, and elongation differ. Select appropriate basic materials according to the efficiency of the target product created. Amongst the above alloys, A356 has the greatest thermal conductivity, and A380 and ADC12 have the least expensive. The tensile limitation is the opposite. A360 has the ideal return strength and the highest possible elongation rate.

About Alcast Company

In accuracy casting, 6063 is appropriate for applications where detailed geometries and top quality surface coatings are paramount. Examples include telecommunication enclosures, where the alloy's exceptional formability enables for smooth and visually pleasing designs while preserving structural stability. Similarly, in the Lights Solutions market, precision-cast 6063 elements produce elegant and efficient illumination fixtures that call for elaborate shapes and excellent thermal performance.

The A360 displays superior elongation, making it ideal for facility and thin-walled components. In accuracy casting applications, A360 is well-suited for industries such as Customer Electronics, Telecommunication, and Power Devices.

Unknown Facts About Alcast Company

Its unique homes make A360 an important choice for accuracy casting in these markets, improving product longevity and high quality. aluminum casting manufacturer. Light weight aluminum alloy 380, or A380, is a commonly made use of spreading alloy with a number of unique attributes.

In precision casting, light weight aluminum 413 shines in the Customer Electronic Devices and Power Tools industries. It's frequently used to craft intricate parts like smart device housings, electronic camera bodies, and power device casings. Its accuracy is exceptional, with tight tolerances approximately 0.01 mm, guaranteeing flawless product setting up. This alloy's superior deterioration resistance makes it an outstanding option for outdoor applications, making certain long-lasting, durable products in the discussed markets.

Alcast Company for Dummies

The light weight aluminum alloy you select will substantially influence both the spreading process and the properties of the last product. Because of this, you need to make your decision thoroughly and take an enlightened technique.

Identifying the most suitable light weight aluminum alloy for your application will certainly suggest weighing a large array of features. The very first classification addresses alloy attributes that affect the manufacturing process.

Getting The Alcast Company To Work

The alloy you select for die spreading straight influences a number of elements of the spreading procedure, like exactly how simple the alloy is to collaborate with and if it is vulnerable to casting defects. Hot cracking, additionally understood as solidification breaking, is a typical die casting defect for aluminum alloys that can result in interior or surface-level splits or splits.

Specific aluminum alloys are a lot more vulnerable to warm breaking than others, and your choice must consider this. It can harm both the cast and the die, so you need to look for alloys with high anti-soldering buildings.

Deterioration resistance, dig this which is currently a remarkable quality of aluminum, can differ substantially from alloy to alloy and is a necessary particular to consider depending on the ecological conditions your item will be exposed to (aluminum metal casting). Wear resistance is one more building frequently looked for in aluminum items and can distinguish some alloys

Barret Oliver Then & Now!

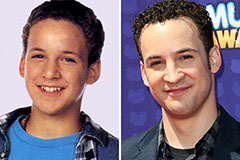

Barret Oliver Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!